JET LINE

JET LINE

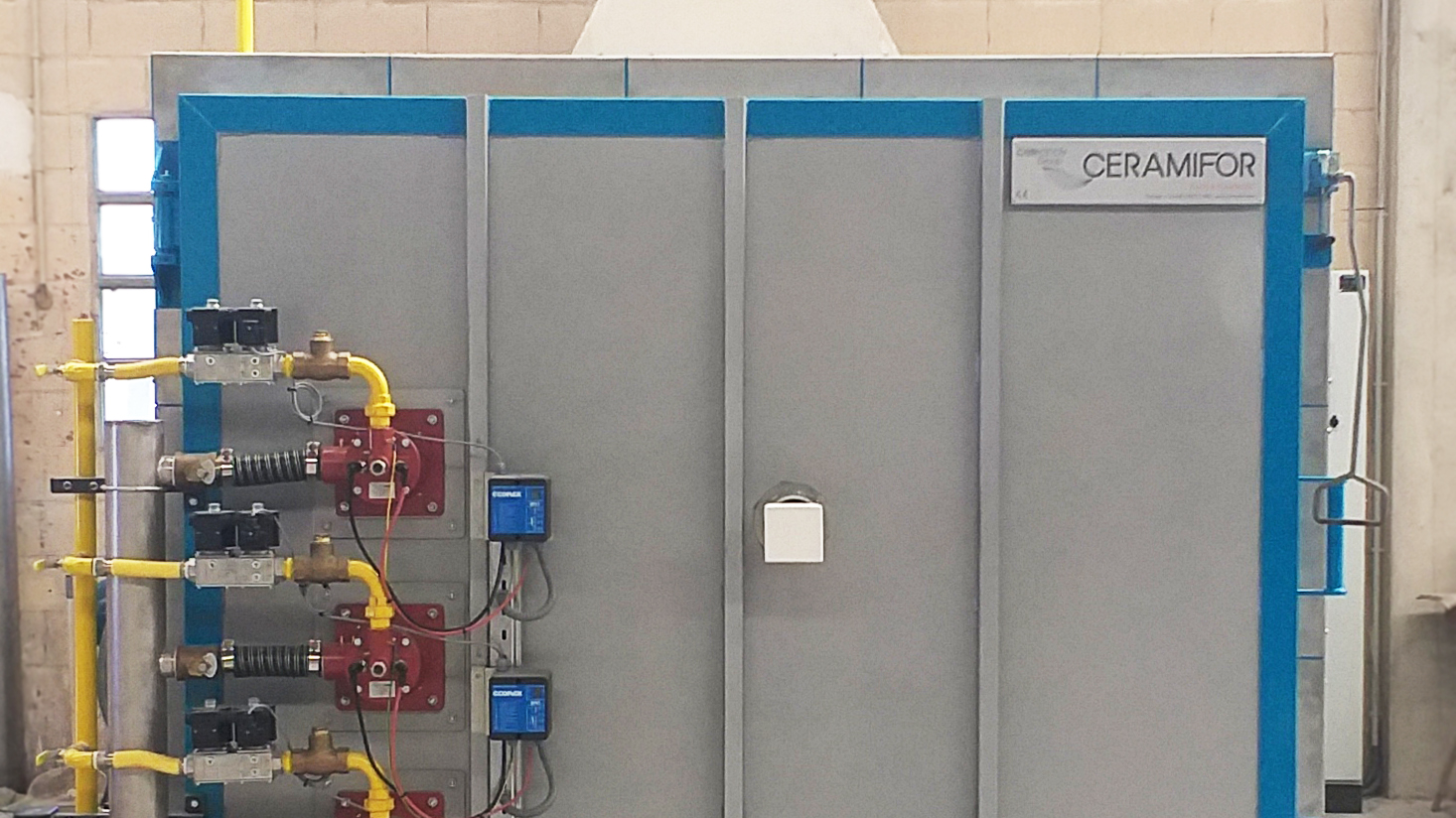

The constant focus on technological innovation together with the know-how acquired over decades, allow CERAMIFOR to present you a range of gas standard kilns, specially designed for earthenware, stoneware, porcelain, sanitaryware, among other applications.

The highly efficient JET Line kilns stands out for:

- A robust construction with a metallic structure using various steel sections, covered with 5 mm mild steel plate;

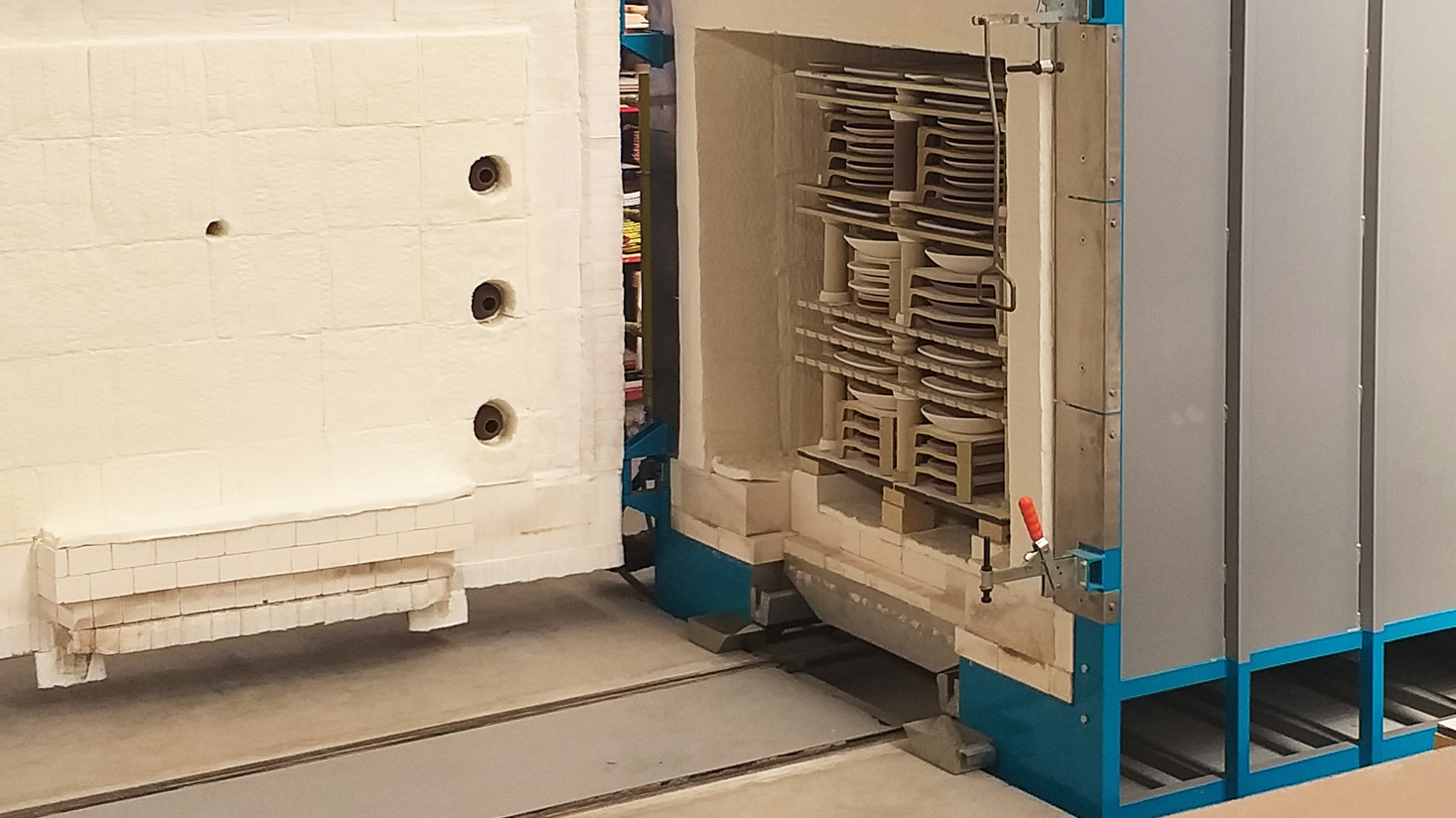

- A quality insulation using refractory brick with high alumina or total insulation with ceramic fiber modules – walls and roof – with advantage to provide faster cycles (up to 4 cycles/day) and higher energy savings;

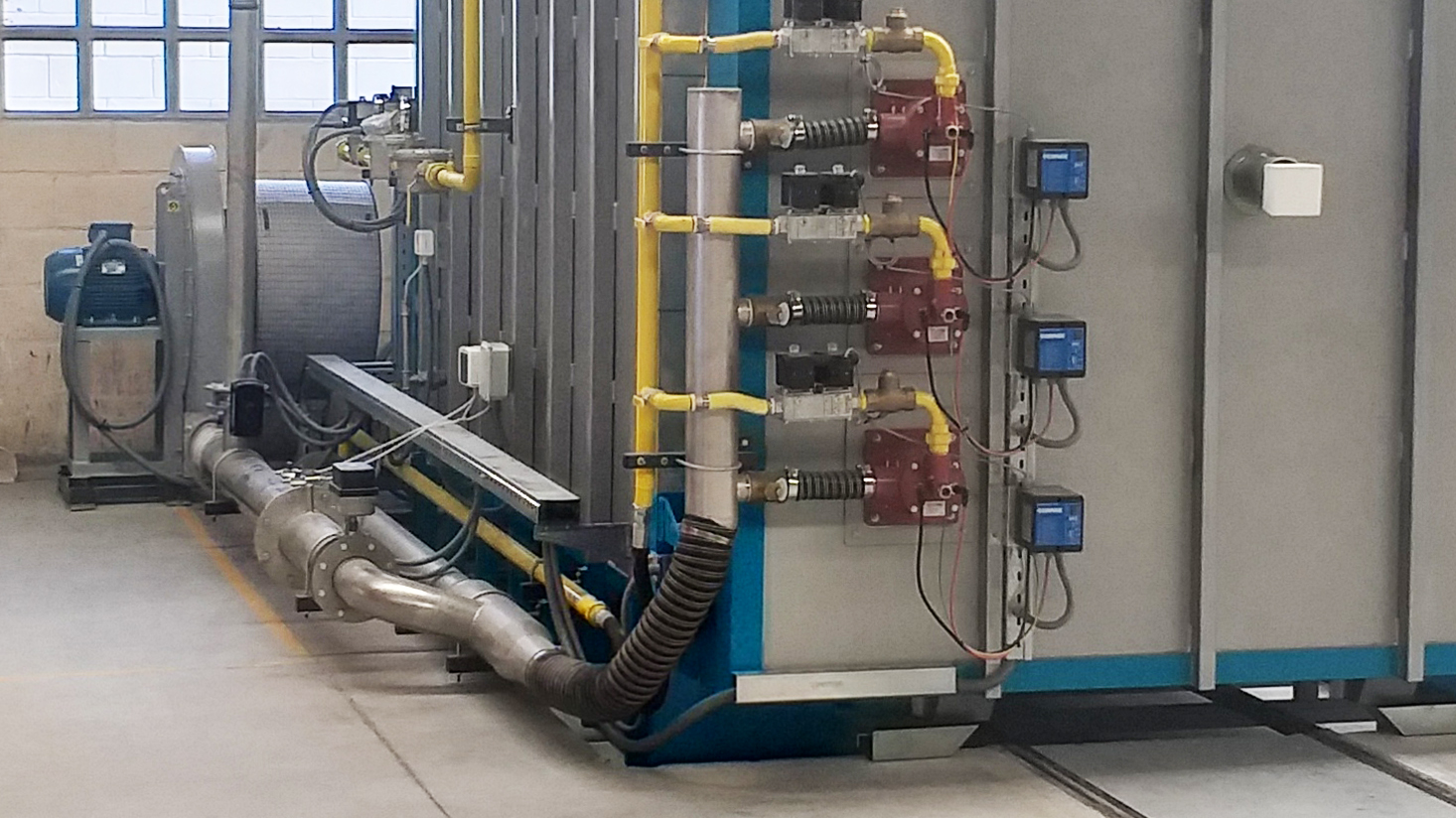

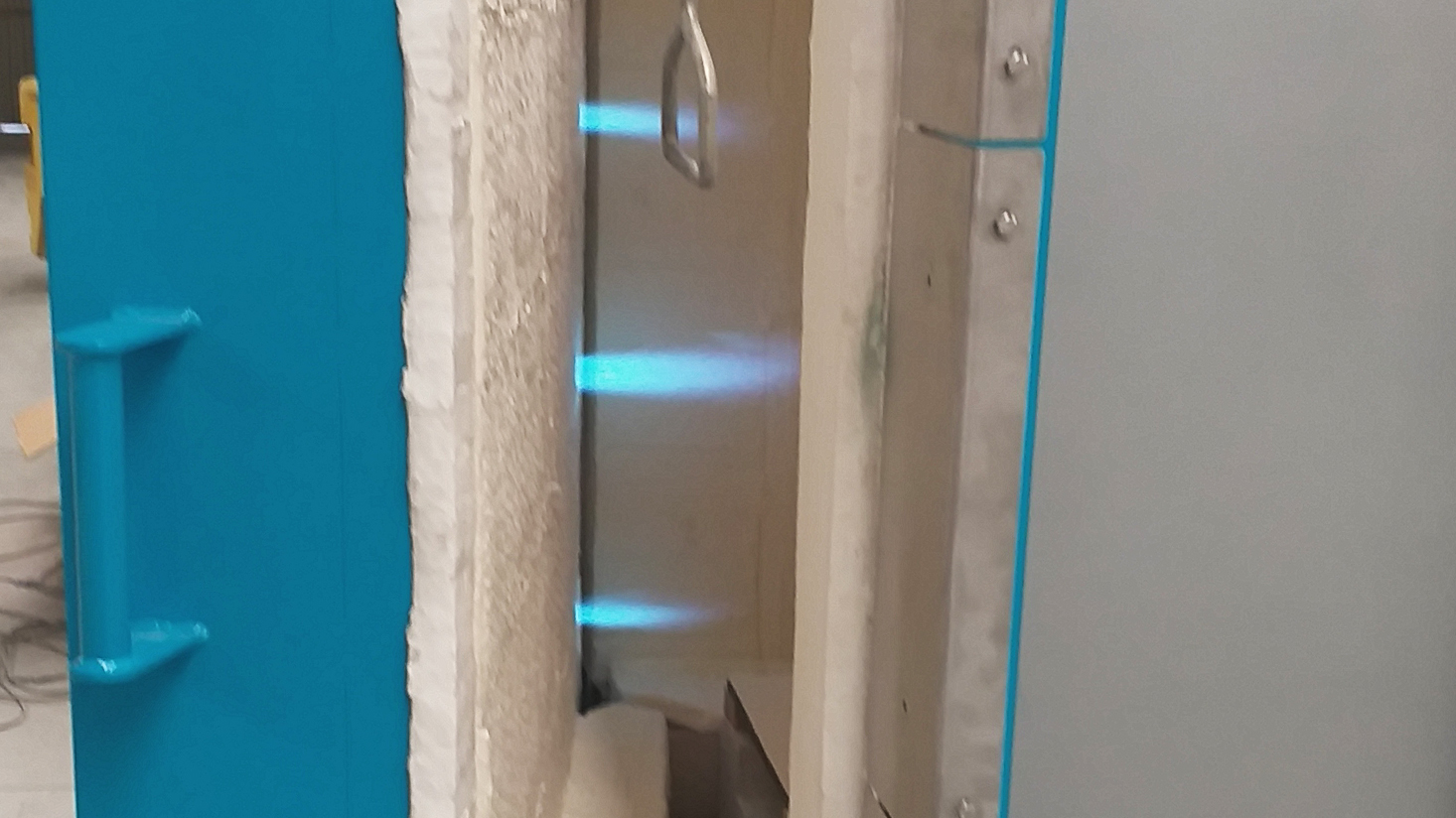

- A sophisticated burning system equiped with high velocity burners (JET) for homogeneous heat distribution in all chamber, with UV or ionization flame individual control;

- A precise temperature control managed by latest generation control system iKCS® (Interactive Kiln Control System) or SPC® (Simple & Precise Control) with total control and broader management capabilities.

Maximum temperature

1400 °C

Kiln construction

Metallic structure using various steel sections, covered with 5 mm mild steel plate

Burning system

Equiped with high velocity burners (JET) for homogeneous heat distribution in all chamber

Temperature control

Latest generation control system with total control and broader management capabilities

Insulation

Refractory brick with high alumina or total insulation with ceramic fiber modules to provide faster cycles and higher energy savings

JET ES

FOR EARTHENWARE & STONEWARE

The JET ES line it is the most cost-effective solution specially designed for earthenware and stoneware firing.

This highly efficient equipment stands out for its quick installation and startup.

- Internal volume (m³): from 2 up to 20

- Max temperature (°C): 1200 / 1300

- Kiln cars inside: from 2 up to 8

- Nº. burners: from 2 to 10

- Thermal power (kW): from 300 up to 2200

- Fan power (kW): from 4 up to 15

JET PO

FOR PORCELAIN

The JET PO line was specially designed to meet the unique requirements of porcelain, vitreous and bone china production.

Its high-quality performance is based on an advanced control of the atmosphere regulated by an air/gas automatic mixture.

- Internal volume (m³): from 2 up to 25

- Max temperature (°C): 1400

- Kiln cars inside: from 4 up to 12

- Nº. burners: from 4 up to 12

- Thermal power (kW): from 600 to 2640

- Fan power (kW): from 5 up to 25

JET SW

FOR SANITARYWARE

The JET SW line was particularly developed to meet the type of loads, as well the specific furniture for sanitaryware production.

Its optimal results stand on a controlled atmosphere regulated by an air/gas automatic mixture.

- Internal volume (m³): from 10 up to 54

- Max temperature (°C): 1300

- Kiln cars inside: from 4 up to 12

- Nº. burners: from 6 up to 21

- Thermal power (kW): from 1320 up to 4620

- Fan power (kW): from 11 up to 35

NEED MORE TECHNICAL INFORMATION?

Please tell us more about you and your project.